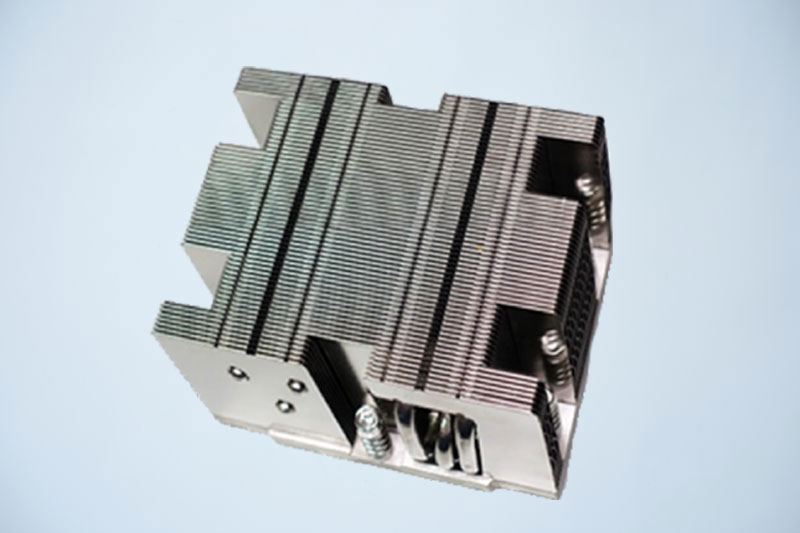

The distance between the spindles is the distance between the fins on the spindles, which can theoretically be 0.2 mm or less, but in actual production, the minimum spacing of the spade-tooth radiator is usually 0.5 mm, 1 mm, 1.5 mm, these parameters are more, and it is not the smaller the spacing, the better, because too small spacing will affect the ventilation and heat dissipation of the radiator, and the stability of too thin heat sink is also affected.

The distance between shovels is specially developed and customized according to the actual conditions of heat sink and heat element, and the following problems need to be considered in the design:

(1) how big a radiator is needed;

(2) whether the shape of the radiator needs to be irregular,

(3) whether it needs to cooperate with forced air cooling, and

(4) whether it needs load-bearing (mechanical factors) .